|

Home

Factory Gage Installation

The 429 CJ Cougar Option

Ford Duraspark Distributor

Inspection Decals

Speedo Gears

429 Engine Detail

Identifying Platings

Rear Sway Bar

Valve Lash Mustang Central

| |

Making Your

Speedometer Gear Accurate

By Dan Davis

First off, the way to get the whole system to

work right is to make the speed cable rotate 1,000 revolutions for every mile

the car is driven. This is done by adjusting the transmission driven to drive

gear ratio on the speed cable to match the tire size and rear axle gear ratio of

the car.

The first thing to know is how many revolutions the tires make in one mile. To

calculate this, measure the diameter of your tires. 26" is about average for

F60-15's or 245-60-15's. Multiply this measurement (26") by pi (3.1416). This

will give you the circumference of the tire. Next, divide one mile in inches

(63360) by the circumference of tire (63360 divided by (26 x pi)=776). This

equals the revs per mile of the tire. Now multiply this number by the rear axle

ratio to give you the number of drive shaft revs per mile (776 x 3.91= 3033).

Next, divide this number by 1000 (3033 divided by 1000 = 3.033). This is the

ratio of transmission driven/drive gears on speedometer cable you will need in

this case use a driven gear with 18 teeth and a drive gear with 6 teeth (18

divided by 6 = 3.0). This is the best choice which yields a 1.1% high error

which means your odometer unit indicates 1.1% greater than actual or 10.11 for

an actual 10.0 miles. If you are using the Ford adapter/reducer (reducer was

factory equipped on cars with 3.91, 4.11 or 4.30 rear axle ratios), multiply the

number by 0.75 (3.033 x 0.75=2.274). This is the driven/drive ratio you need. A

3.75% error (i.e., a 0.375 mile error in 10 miles) is considered acceptable by

design.

When picking a driven/drive gear ratio to match the tire and rear axle gear

ratio you have a choice of drive gears and driven gears.

The drive gear is inside the transmission and the tail housing must be removed

to get at it. You may be able to see what gear your transmission has by looking

in the hole where the speedometer cable goes with a light. Manual transmissions

have a plastic gear pressed onto the output shaft. The manual trans drive gear

is also color coded: pink (6 teeth) or black (7 teeth). Toploaders use the "type

4a" drive gear while automatics use a gear machined to the output shaft with

either 8 or 9 teeth. Automatics have a metal gear machined into the output

shaft. To change the latter, the whole output shaft must be changed, a big job.

The driven gear clips onto the end of the speed cable. These plastic gears are

unique between the manual Toploader transmission and the gears in an automatic

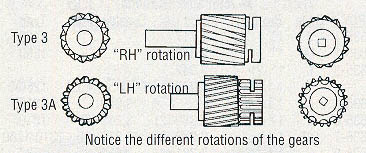

transmission. The uniqueness is due to the helix direction of the gear teeth.

This is the curvature as seen when looking at the gear teeth. The automatic

transmissions are right hand helix (known as type 3). The speedometer cable

enters the transmission on the driver's side of the car. The Toploader

transmissions with the shift linkage outside of the transmission are left hand

helix (known as type 3a). The speedometer cable enters the transmission on the

passenger side.

All driven gears are color coded whether they're used with an automatic or

manual transmission The automatic and today's manuals are molded in color. The

Toploader driven gears are molded in off-white colored plastic and the tips are

color coded with paint.

Your choices are (tooth count and color code): 16 (blue for AT, orange for MT),

17 (green AT, purple MT), 18 (grey AT, green MT), 19 (tan AT, pink MT), 20

(orange AT, blue MT), 21 (purple AT, red MT) and 23. The 23 tooth gear is from

Saleen (

http://www.saleen.com/store2000/detail_new.asp?car=saleen&prodid=047-280 )

and costs $22, but the teeth are thin and the gear will wear out every couple of

years. If you cannot make it work with this stuff, you have one more option --

get a reducer box like Ford used with Drag Pak cars. The original is spendy

(~$350), but a generic box can be had from a speedo calibration shop for a lot

less. I would chose this method over changing the output shaft on an AT unless I

had to remove the trans anyway

Here is a handy chart to chose your gear combo after you have done the math

shown in the first paragraph. The ranges shown comply with the Ford approved +/-

3.75% allowable error:

Toploader choices:

16/6 = 2.567-2.767

17/6 = 2.728-2.940

18/6 = 2.888-3.113

19/6 = 3.048-3.286

20/6 = 3.209-3.459

21/6 = 3.369-3.631

23*/6 = 3.690-3.978

16/7 = 2.200-2.372

17/7 = 2.338-2.520

18/7 = 2.475-2.667

19/7 = 2.610-2.814

20/7 = 2.750-2.964

21/7 = 2.888-3.113

23*/7 = 3.163-3.409

C4 & C6 choices:

16/7 = 2.200-2.372

17/7 = 2.338-2.520

18/7 = 2.475-2.667

19/7 = 2.610-2.814

20/7 = 2.750-2.964

21/7 = 2.888-3.113

23*/7 = 3.163-3.409

16/8 = 1.925-2.075

17/8 = 2.045-2.205

18/8 = 2.166-2.334

19/8 = 2.286-2.464

20/8 = 2.406-2.594

21/8 = 2.527-2.723

23*/8 = 2.767-2.983

16/9 = 1.711-1.845

17/9 = 1.818-1.960

18/9 = 1.925-2.075

19/9 = 2.032-2.190

20/9 = 2.139-2.305

21/9 = 2.246-2.420

23*/9 = 2.460-2.652

* = Saleen part, not Ford part

Hope this helps!

--

Regards,

Dan Davis

**************************************************************************

Another Speedo Gear resource that may be of help is located

on the 428 Cobra Jet Mustang Registry website;

Mustang 428 Cobra Jet Speedometer Gear Calculator

|

![]()

![]()